Case Studies

Featured Project

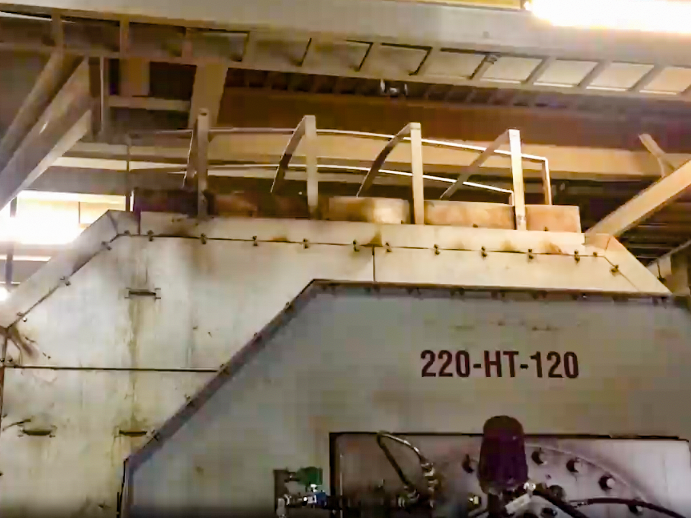

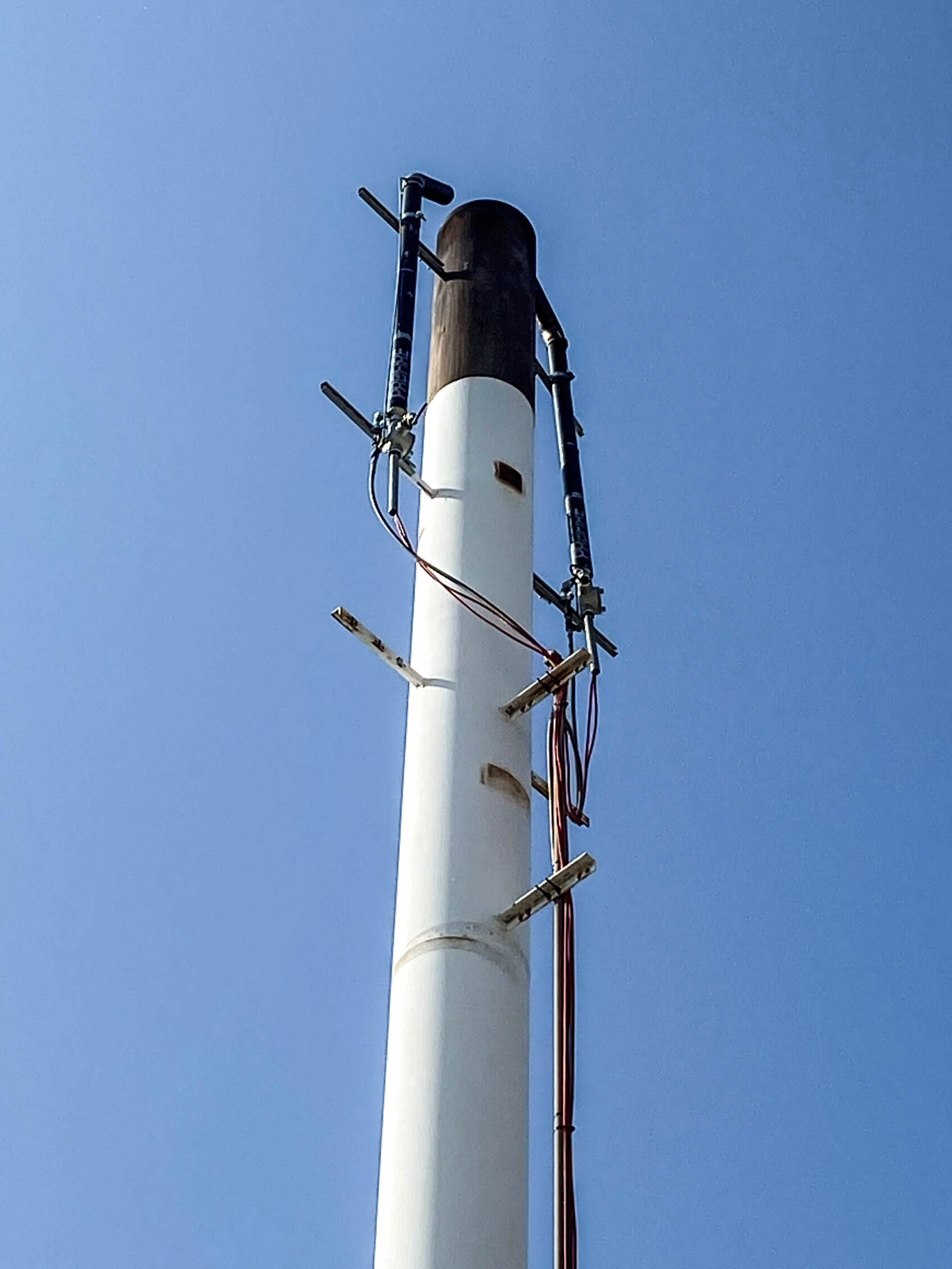

Line Heater Upgrade

Line Heater

The Profire Team installed new arrestor housings supplied by the customer to allow adequate secondary air flow for complete combustion. In addition, the outdated fuel trains were upgraded to provide additional reliability, safety and independent burner tube control. Two Profire PF2100 controllers were installed to provide temperature control, auto re-lights and flame detection for safe operation. Overall, the Profire solutions were able to significantly improve the operation of the heater by achieving the desired heat output in a safe and reliable system.

View Case StudyRecent Projects

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

One of our long-term customers faced the serious risk of regulatory penalties at the local, state,…

Our client had a unit with extremely dangerous and violent initial starts. The potential of equipment…

Operational failures experienced during inclement weather conditions coupled with inconsistent performance with the original pilot and…

Our client came to us feeling frustrated with the inefficiency of their Burner Management System. The…

Ensign was experiencing nuisance shutdowns with limited safety I/O. The heater was going down 2-3 times…

The client purchased a second-hand Bryan Boiler with outdated controls and inefficient air to fuel ration…

This heater was unable to achieve the necessary temperatures required for operations because of airflow and…

An upstream customer required a safer and more reliable burner management solution for their heated process…

It was critical for National Grid to meet compliance standards and create a safe working environment…